Slovenian Steel Group, d. d.

Key benefits of RAVNE KNIVES

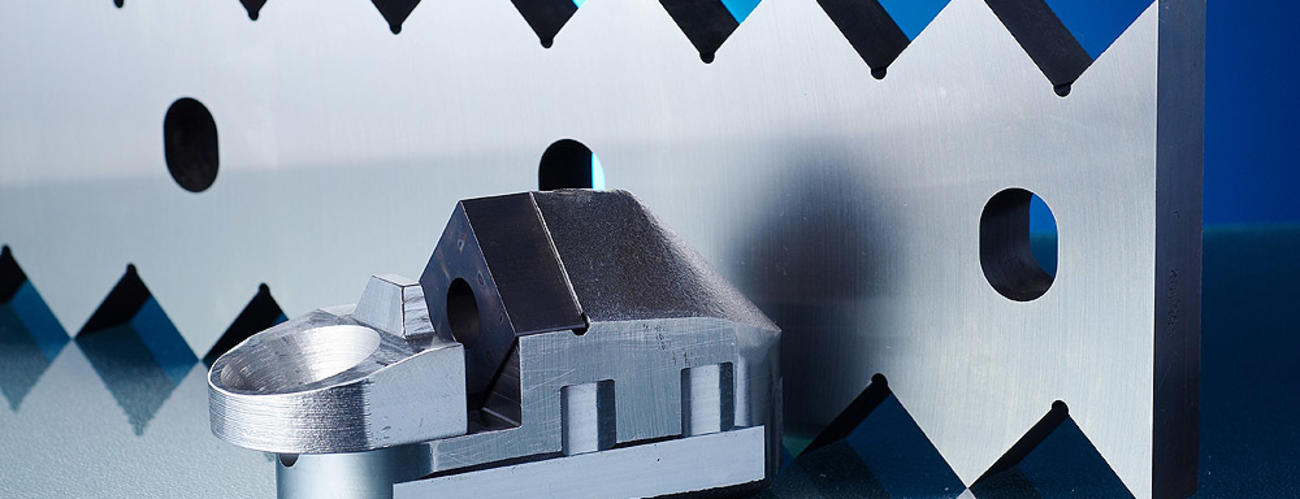

Knife manufacturing technology at SIJ Ravne Systems has evolved tremendously over the years to meet the increasing demand for cost-effective top-quality knives for specific industrial applications (metal industry, recycling, wood and wood processing industry and also paper and tire industry).

Our 50 years of experience and cooperation with leading machine builders (OEM) in R&D projects and knife users worldwide means we can customize knives to suit your specific application and special requirements.

SIJ Ravne Systems is a part of SIJ Group and as such remains the only knife manufacturer in the world within an integrated vertical supply chain with access to its own tool steel.

Cutting Costs and Product Loss with Innovative Industrial Knives:

• Maximized lifetime – we use advanced high grades of tool steel and heat treatment procedures to ensure the best ratio of hardness to safety against cracking.

• Maximized precision – we have a specialized machine park which enables us to achieve the best possible dimensional and geometrical tolerances, ensuring optimized performance and precise gapping.

• Quality Assurance – our own non-destructive test laboratory provides a new perspective on product safety by focusing on the prevention of internal defects to minimize the risk of knife breakage.

REDUCE the overall TCO

RAVNE KNIVES are better value in the long run and have lower total costs of ownership (TCO).

To reduce the overall TCO throughout a knife's life cycle and create additional value for users, we have increased service life by up to 100%. This means longer periods between knife replacements, less machine downtime and lower resharpening costs.

COMPARISON OF STANDARD MARKET KNIVES AND RAVNE KNIVES

SIJ Ravne Systems focuses on providing high-quality knives that make high-quality cuts and have a longer service life.

There is always something new to discover in the world of industrial knives.